Swellable Packers

- AER has 98% success with getting swellable packers to TD with use of our technology and reamer tools

- AER understands the interconnected relationship of borehole quality, T&D, Directional Drilling and Packer Design

- Several Swellable Packer Patents & Technology – AER Patented End Ring Design

- Superior bonded element, not slip-on

- Testing with research capabilities – engineering support and manpower assets

- AER provides service and support throughout the purchasing process that ensures performance success

- AER employees have hands-on experience relating to providing reamers and swellable packers on hundreds of wells

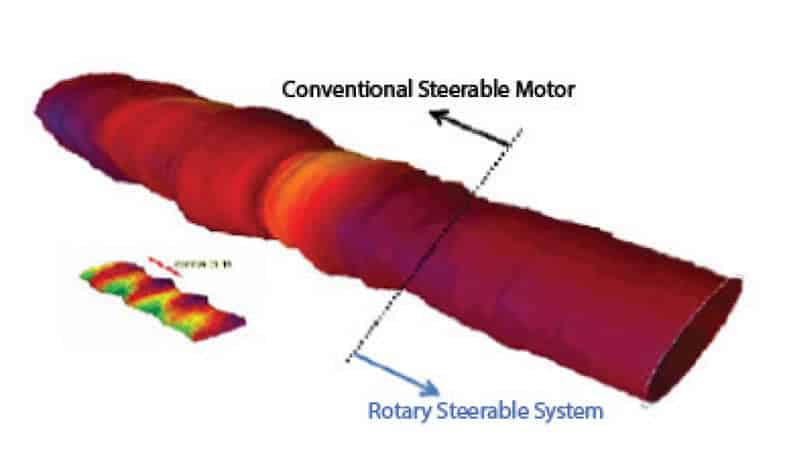

Integrated Insights

Think of swelling packers and ‘rubber’ is the first thing that comes to mind. But AER, Inc. has taken packer design a step further with development of a robust new End Ring design that incorporates aspects of drill bit technology which enable packers to be run to bottom smoothly and quickly, every time. Designed to provide protection to the rubber element during packer run in, the End Ring Cap is applied after the rubber element is vulcanized to the base pipe to establish an effective annular seal which prevents extrusion during sealing and production. Based on extensive knowledge of drill bit design, AER further refined the End Ring cap with addition of high junk slots and PDC cutters which afford rotation and provide a solution in open hole completions. Integrating drilling and completion concepts, AER’s solution was quickly adopted in Bakken shale wells, where as many as 40 swelling packers per well are now smoothly installed as a matter of course.